I’ve learned a lot about acetoxy silicone, but most of what I’ve learned is I have no idea what’s going on and I just try to make it do something resembling what I want, but not be too picky. I haven’t found much information online about using silicone this way, so I figured I’d make some notes about it.

DIFFUSION

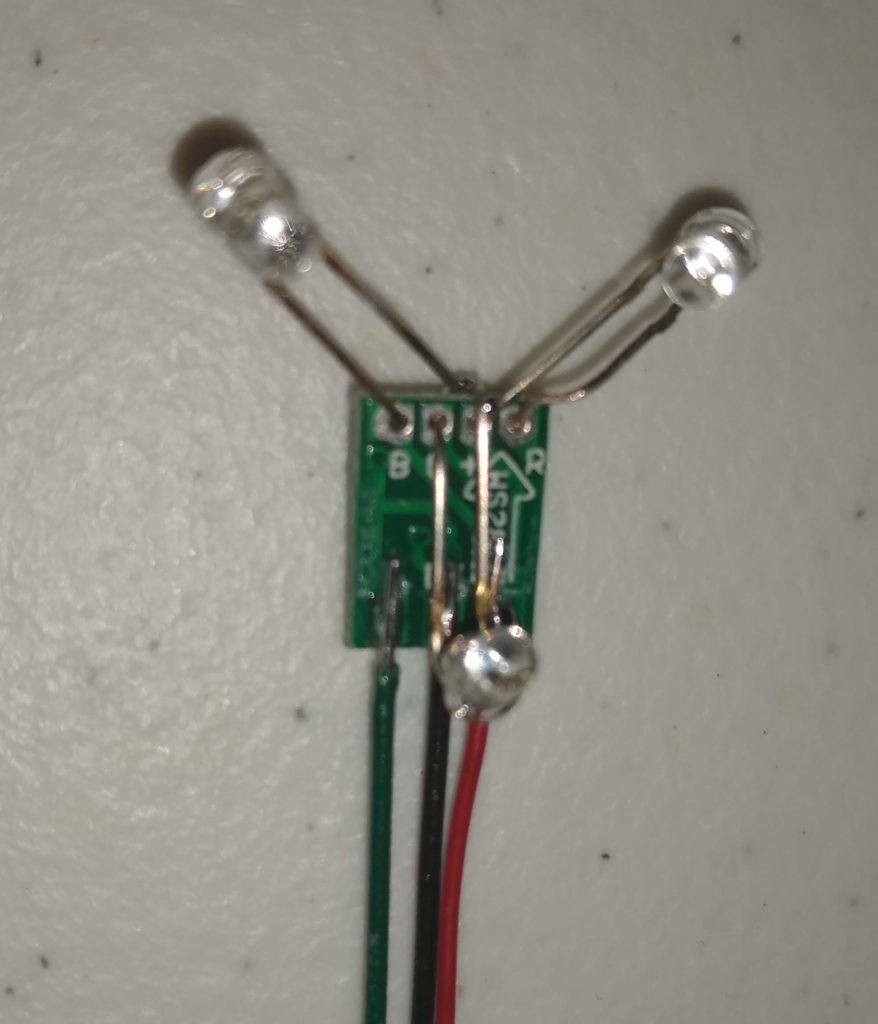

Silicone make a uniquely perfect transparent diffusion. It somehow transmits and bounces enough light that a few LEDs can fill up a volume with light, and show a little of the ‘beam’, but the volume remains transparent. I’m not sure what makes it so perfect, but I’ve tried several other clear fluids and this silicone does this kind of diffusion better than anything I’ve tried. And so far this DAP Ultraclear acetoxy cure silicone is the only kind that’s water clear and still workable. I found some loctite adhesive that’s as clear, but it’s a different chemistry and hardens weirdly and just doesn’t work, also it has a slightly yellowish tint. I guess epoxy resin might have a similar effect with light, but it’s expensive and I think UV messes with that over time. For whatever reason clear silicone just makes a beautiful substrate for lighting little miniature scenes.

CURING

As I understand it there’s something called ‘cross-linking’ going on where H20 molecules are exchanged from the air with acetic acid in the silicone. That process is what solidifies the silicone. I only have the vaguest idea what that means chemically.

When you lay in the silicone as thick as the balsa tubes, it seems to ‘self-heal’ any interfaces between silicone layers. Very small bubbles in ridges between ‘beads’ tend to go away quickly. Bubbles up to about 3mm in diameter seem to go away within about a week.

I’m not sure these tubes will every fully cure. So far the oldest tube I have is about 4 months, and it’s still a bit malleable in the middle. You can push the whole scene up or down a few mm by pressing the ends. Pretty sure it’s just forming a ‘plug’ of cured silicone that eventually gets large enough to stop any deeper curing. But it does keep going for a while. I’ve found if I seal the ends flush, within about a month I’ll need to ‘top off’ the tube because it’s shrunk about 4-5mm in. I’ve started adding a layer of cling wrap once they’re in the lights but I’m not sure if they’ll just slowly shrink for years and end up looking crazy with big domes pulled in from either end.

Pre-cured silcone slabs with powder and glitter seem to blend into fresh silicone over time. The interface disappears within a day and you can only see the inclusions. I’ve pulled dioramas apart after about a month and it seems like the pre-cured silicone softens considerably. When pulling apart the silicone it has a uniform viscosity in the center, even in places where the pre-cured silicone layers were previously very solid.

I’ve had no big breakthroughs in speeding up the curing process. I haven’t been very scientific with control groups, but I have some observations:

MOVING AIR – I just put a fan on it. Seems like that has to do something. If you leave curing silicone in a closed space it starts to smell strongly of vinegar, so makes sense clearing that out with a fan might move things along.

MOISTURE – I’ve tried submersion, vapor, and mist. Submersion does nothing, almost seems like it prevents curing somewhat. Vapor and mist seem to help harden up the outer layers, but I don’t know if that’s actually bad for curing deeper within the silicone. I do notice that if you put an older tube in a closed space with a mister, it starts to smell more strongly of vinegar than in a dry space. So maybe it’s doing something and I’m just too impatient.

HEAT – I left them in my car on a hot day, submerged in nearly boiling water, and used a USB heater to keep them about 60C for a day. I destroyed about 3 tubes in the process. The PLA gets soft about 80C and things get weird. I might try to keep it closer to 40C for a day or two, but so far seems like heat causes more problems than it’s worth.

UVC – I got a 8W UVC tube light. Made a little black out box and stuck it in with a tube. It does something because you smell burnt rubber as soon as you turn it on, but after a couple of days it didn’t seem to cure any faster and the PLA was starting to fade. I’m guessing the UVC only penetrates a little bit and just cooks the silicone on the top and does nothing deeper in. Anyway I knew it was probably a bad idea, but I had the light and couldn’t not try it.

PRESSURE – I have a USB food vaccum pump that I was hoping would help get some bubbles out, but it doesn’t. I would like to see if possibly raising the ambient pressure a bit could help speed the curing process. Ideally a small chamber capable of 2-3atm with humidity and heat control, but I live in an apartment and my kitchen is insane enough as it is so that’ll have to wait.

SOLDER CLOUD

The ‘nose weight’ on the balsa planes seems to create a yellowish cloud over time. It takes months and isn’t very noticable, but it’s very consistent. It expands out perfectly radially around the nose weight. Something is leeching out into the silicone, possibly tin or the rosin. You can only really tell with the LEDs off and held up to a light, so it’s not a big deal, but I may try to find a different material for the nose weights.

WATER

Keeping your fingers wet allows you to handle fresh silicone to some degree. It’s useful for smoothing and patting layers into each other. But it does seem to introduce a cloudyness in thick silicone. You can only really use water on the outer layers.

G-FORCE

I figured I could move things around in the silicone with a kind of centerfuge so I made a kind of sling. As a test I used a 6″ section of 1″OD tube filled with fresh silicone. I put a couple of bismuth beads at the top. I figured if anything would move in the dense silicone it would have to be pretty dense. Very rough calculations of the radius and rpm spinning it by hand I got about 9G’s and kept that up for about 20m. I manager to move the beads all the way through, but they jammed up against the tube wall as they went down. I figured there’s no way to use that so that’s about as far as that whole thing went. I’m sure a more precise and powerful centerfuge could do better, but not sure if there’s a point.

CLING WRAP

Counterintuitively, cling wrap is the best material I’ve found for kind of ‘molding’ silicone. I tried aluminum foil and wax paper. Foil tears when you try to get it off, and wap paper leaves a residue even if it doesn’t tear. I also tried thicker sheets of plastic and the silicone tears when pulling it up. Cling wrap is flexible and strechable enough to remove from silicone if you let it shrink onto it. It doesn’t work as well if you ‘pre-strech’ the cling wrap like a canvas. It also works okay on fresh silicone if you peel it back very quickly. It will stick, but it leaves a fairly smooth interface.

GLYCERINE

I need to do some more testing with this as a release agent and such. I also wonder if a a ‘vape’ device generating glycerine vapor could help speed up the curing process, but haven’t figured out how to test that without things getting very messy.

SILICONE MOLDS

I ordered some of those molds they use for epoxy resin, but they never came in. Still not sure if these would even work or if the silicone would bond too well. They do make some cool shapes though so I may still give these a shot.

OTHER STUFF

I think I’ve tried injecting pretty much every household chemical I have to see what everything does and looks like when injected in clear silicone. Most stuff just looks like what you’d expect. vegetable oil, bleach, various glues, other silicones, detergent, goo-gone, acetone, and my favorite experiment- alka-seltzer. Nothing really did anything that interesting, execpt alka-seltzer- I ground up a couple of tabs and cured it in a tube for a few weeks, then injected water into it. It did about what you’d expect- just slowly pooed out the silicone. It was unimpressive, but worth mentioning I guess.